PRODUCTS

Valve Assemblies

At Airpack with an experience of more than 40 years, strenuous efforts are made to perfect the Valve Assemblies in all its facets.

From selection of appropriate raw material to the final leak check our skilled workmen follow stringent quality parameters for manufacturing these valves.

CNC Turning and CNC machining centers imported from USA are used to machine the Valve Seats, Studs and Guards.

We possess outright capabilities for Reverse Engineering of the valve Assemblies.

We can also Design New Valves for highest efficiency, maximum service life and also for specific applications.

Metallic Valve Plates and Rings

From traditionally designed metallic valve plates to the latest high performance non-metallic valve internals Airpack manufactures a wide range of these components utilizing the sophisticated and latest manufacturing techniques.

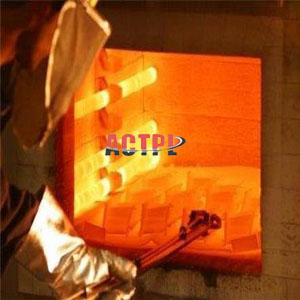

Laser metal cutting technologies, our in-house Heat Treatment facilities, fine Grinding, Lapping, Deburring and Polishing are used to give complete accuracies and extra strength to the Valve Plate, Spring Plate and Damper Plates.

We use Stainless Steel 420 , 17-4ph, 17-7ph, Inconel, Titanium, etc. for manufacturing the metallic plates. Also different grades of PEEK, MT or Nylon is used for perfecting the non-metallic plates.

The material can also be selected according to its special application requirements of the customer.

Valve Repair Kits

We also offer customized valve repair kits, enabling your Compressor maintenance.

Standard Maintenance kits include:

- Valve Plates

- Spring Plates

- Damper Plates

- Guide Rings

- O Rings

- Springs

Your Unique Service Kit

- Ready stock

- Quality Assured

- Delivery Prompt

Thermoplastic

- Corrosion free

- Chip Free

- Fracture Free

At Airpack we develop thermoplastic components in varied sizes and different grades like Peek, Carbon Peek, Nylon, MT, MTX, etc.

Keeping in mind its highly essential properties we source supreme quality raw material for:

- Maintaining its tensil strength at par

- Metal like level of toughness

- High temperature and chemical resistance

- Better Lubrication

- Improved Efficiency

Piston Rings and Rod Sealing Rings

- Piston Rings

- Rider Rings

- Rod Sealing Rings

- Scrapper Rings

At Airpack we manufacture Piston, Rider and Sealing Rings and are designed to provide accurate mechanical seal, minimal leak paths and durability in the most demanding applications.

Looking into the required sealing, precision, tolerances and accuracies, the technique of manufacturing various rings is unique and has been practiced and perfected by AIRPACK over the years

Stringent quality checks and procedures give us confidence that our Rings will perform perfectly with the end user.

Different grades of PTFE, Bronze, Gun Metal, Babbit & Stainless Steel are used for manufacturing of various rings as per OEM standards and also as per user requirements. Our highly experienced personnel test and analyze the raw material before taking up in the manufacturing process.

Pistons and Piston Rods

At Airpack our vast experience in manufacturing makes us a reliable source for a wide range of Compressor Pistons and its Rods.

Pistons are manufactured as per customer requirements and compressor applications. They are made of Alloy aluminum, Cast Iron or any special material as required.

Rods are made on precision machines, induction hardened and perfectly grinded for excellent finish. We also do Thread Rolling on the Rods to give extra strength.

Reverse Engineering can also be done for the Pistons and Rods

with the help of Our material analyzing laboratory and in-house drawing facilities.

Gaskets and O Rings

Our highly knowledgeable manufacturing team is a trusted source for the Custom Made Gaskets and O-rings providing high Performance guarantee also in extreme working conditions.

We use special materials as per the requirements for manufacturing the Gaskets.

O-rings are made almost exclusively of synthetic rubber or plastic polymers with elastomeric properties, and are produced solely in ring form.

O-rings can be manufactured in varied materials like Silicon Rubber, NVR, EPDM, Nitrile, Buna, Flexible Graphite, Viton, Neoprene, etc.

O-rings can be manufactured in varied materials like Silicon Rubber, NVR, EPDM, Nitrile, Buna, Flexible Graphite, Viton, Neoprene, etc.

We can also do reverse engineering for the existing component to develop and match the originally designed dimensions and working specifications.

Bearings and Bushes

- Big and Bearings

- Main Bearings

- Bushings

At Airpack our technocrats with their vast experience manufacture a wide range of Sturdy Bi-metal Bearings & Bushes, which are being widely used as perfect replacement part for various Compressors, Engines, etc.

These are manufactured by centrifugal as well as sintered process for various applications.

Machined And Turned Parts

Airpack is serving the Industry with precisely engineered components that includes Precision CNC Turned Components, Precision CNC Milled Components, Industrial Components, Forged Components, Carbon Steel / Alloy Steel Castings, Stainless Steel Components. Our range of products find extensive application in various industries.

We have latest CNC machines for manufacturing of different types of high precision components. Our products are manufactured under the supervision of highly skilled professionals and very stringent quality checks are done while in process and also in process sizes are monitored by our qualified and experienced Quality control staff for accuracies and the correct machining.

Reverse Engineering can also be done if samples are provided. We send material for analyzing the composition for selection and full manufacturing drawings are made before we start manufacturing process on them.